Laser Cladding Services Uk

Pm laser cladding llc is a multi product engineering company operational since 2011.

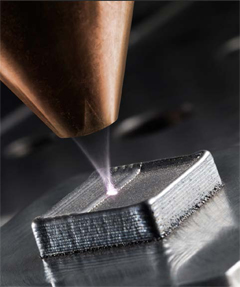

Laser cladding services uk. Laser cladding is realized either as wire laser hot wire cladding or powder cladding. Due to its superior focusing ability lasers allow power densities that are not typically possible with conventional thermal procedures. Very low total heat input automated laser systems precisely control heat input for your part allowing for minimal dilution of the overlay with the base material and results in a very small heat affected zone. Has built its reputation with some of the uk s largest blue chip organisations and provides services to a multitude of industries where using the laser cladding.

The laser beam creates a molten pool at the workpiece surface to which is simultaneously added the laser coating material wire or powder molten by the laser. Laser cladding services is now part of oerlikon metco. Components being laser clad are exposed to higher temperatures than traditional thermal spray produces so care. Laser cladding technology ltd.

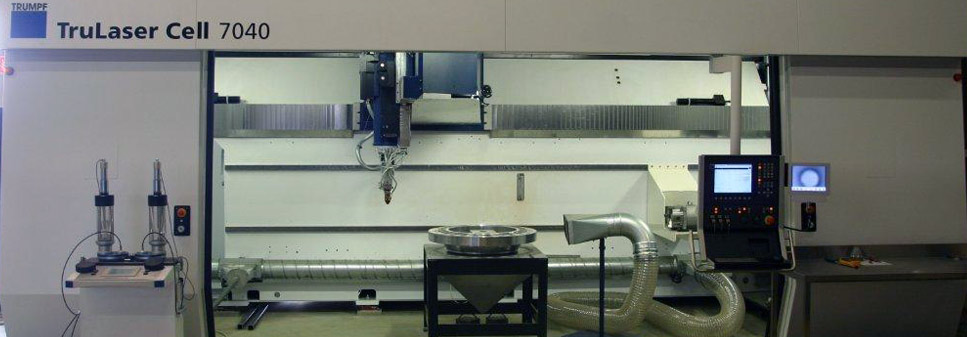

Laser cladding also known as hard facing or weld overlay is where a material with a much higher wear resistance is welded onto the external surface of a typically expensive component. We are focused on supporting our customers with specialized components and innovative surface engineering products and services. Oerlikon metco is a leading surface solutions provider with a global presence. Laser cladding services since 1988 we have been developing laser welding services for a variety of applications in different industries ranging from medical parts to gas turbine components.

Formed in 2003 as a joint venture with technogenia sa france has become the largest laser cladding provider in the uk. Laser cladding technology ltd. Alternatively you can call us on 01909 470589 or email sales lasercladding co uk. Visit our site to find out more.

Laserbond is a specialist surface engineering company that aims to increase operating performance of machinery components. The cladded materials are often composite in nature where ultra hard particles are supported in a more workable allow e g. Fill in the form below and we ll contact you as soon as possible. We have a team of engineering professionals manning a diversified portfolio consisting of hydraulics metal surfacing hardening manufacturing cnc machining distribution and services.

The exposure time is short which creates only a short delay as the cooling is quick. Creates a metallurgical bond laser cladding creates a metallurgical bond between the base material and the overlay that will not flake away. Laser clad overlays are excellent in a wide range of applications but the higher cost of a welded overlay when compared to a thermal spray solution often demands that laser cladding services are primarily specified for only the most extreme applications.