Laser Cutting Cycle Time Calculator

Cutting macro calculator there is an overwhelming amount of information for weight loss out there.

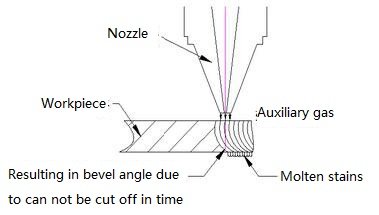

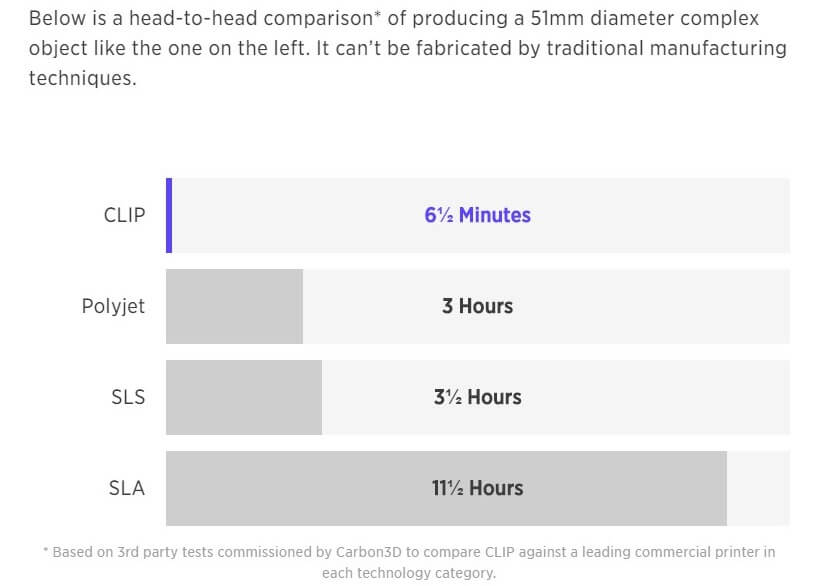

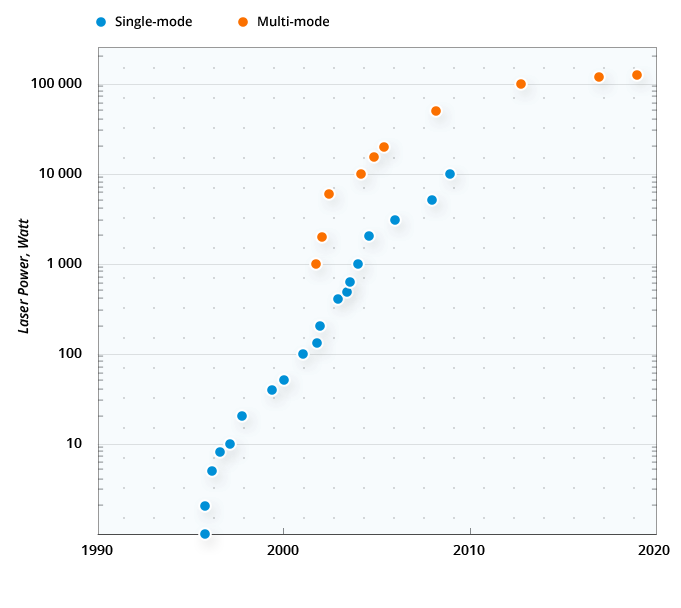

Laser cutting cycle time calculator. And thinner while the advantage for punch plasma increases as material gets thicker. Standard entrainment abrasive water jet cutting head 2 2 laser cutting there are two commonly used types of industrial cutting laser co2 and nd yag. The cycle time formula is an essential manufacturing kpi to understand in manufacturing. These differ in that the wavelength of infrared light produced is 10 6 µm for co2 lasers and 1 06 µm for nd yag lasers.

We wrote this calculator that factors in current best practices for determining your daily caloric needs and then applies our own diet to help you shred fat while preserving muscle. Some customers asked me how can i know how long will it cost cost it cost to to make a working piece before i sta. Get a test cut wardjet is an ohio based designer and vertically integrated manufacturer of tailored waterjet cutting solutions that are used to cut materials ranging from tinfoil to titanium. From the feed and spindle speed.

In the heaviest thickness the punch plasma maintains a 40 percent cost advantage over laser cutting. To calculate your material cutting speed and waterjet pump pressure download the kmt 60 000psi 90 000psi cutting calculator on your computer. Hi everyone this is amy from thunderlaser. Answer first calculate the cutting length per min.

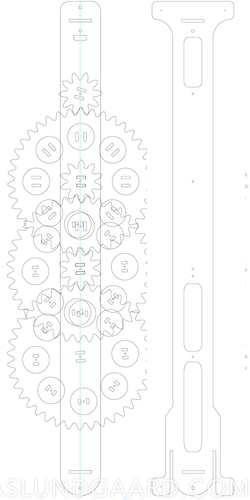

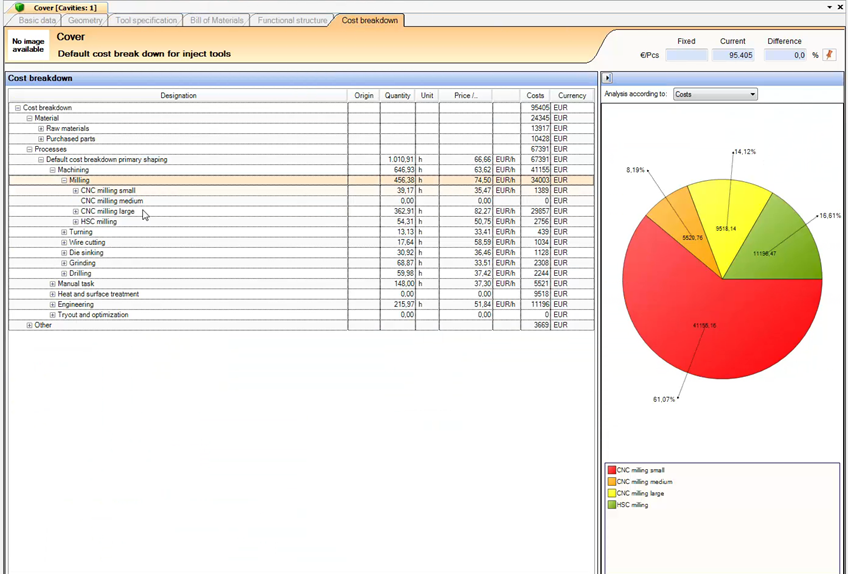

It is used by erp and mes systems for scheduling purchasing and production costing. Problem what is the cutting time when 100mm workpiece is machined at 1000min 1 with feed 0 2mm rev. The costimator lasercut cost model will calculate the time and cost to lasercut a part with four input variables. Both these types of lasers cut by focusing a.

Laser cutting offers a lower cost for material about 12 ga. It is also a critical part of the oee calculation use our oee calculator here fortunately it is easy to calculate and understand. Material type and thickness cut distance and number of holes. Based on these inputs the cost model will calculate the appropriate cycle time and cost per piece.

That s right watch remotely as your part is being cut.