Laser Cutting Time Calculator

The costimator lasercut cost model will calculate the time and cost to lasercut a part with four input variables.

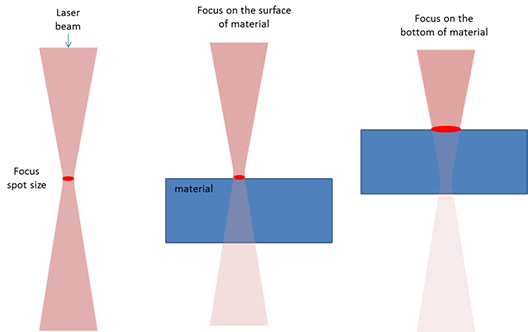

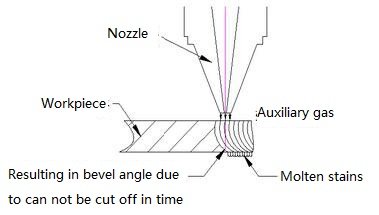

Laser cutting time calculator. Enjoy the videos and music you love upload original content and share it all with friends family and the world on youtube. Laser cutting in the processing of the limit material is inefficient and the effect will be reduced cannot be continuous processing. Things to be aware of are the. The cutting capabilities of the laser is directly proportional to the beam quality and beam waste of the laser.

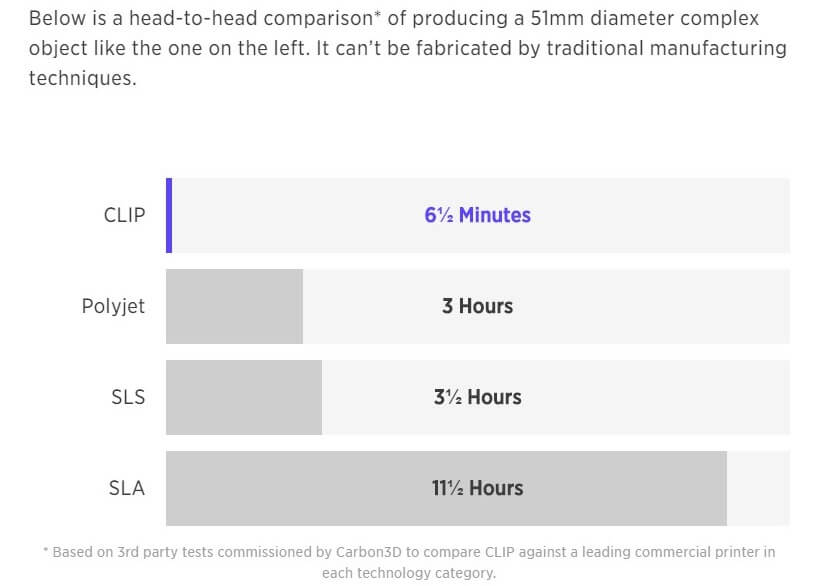

Laser cutting offers a lower cost for material about 12 ga. Mid level computer with windows 7 810 800 1500 vector designing software. To start your small business you need a minimum. And thinner while the advantage for punch plasma increases as material gets thicker.

Based on these inputs the cost model will calculate the appropriate cycle time and cost per piece. Cost and price calculator 12 1 business starting requirements. Disk calculator can be used to calculate the recording time with a given disk space and calculate the disk space with a given recording time. Costing from 500 6000 computer.

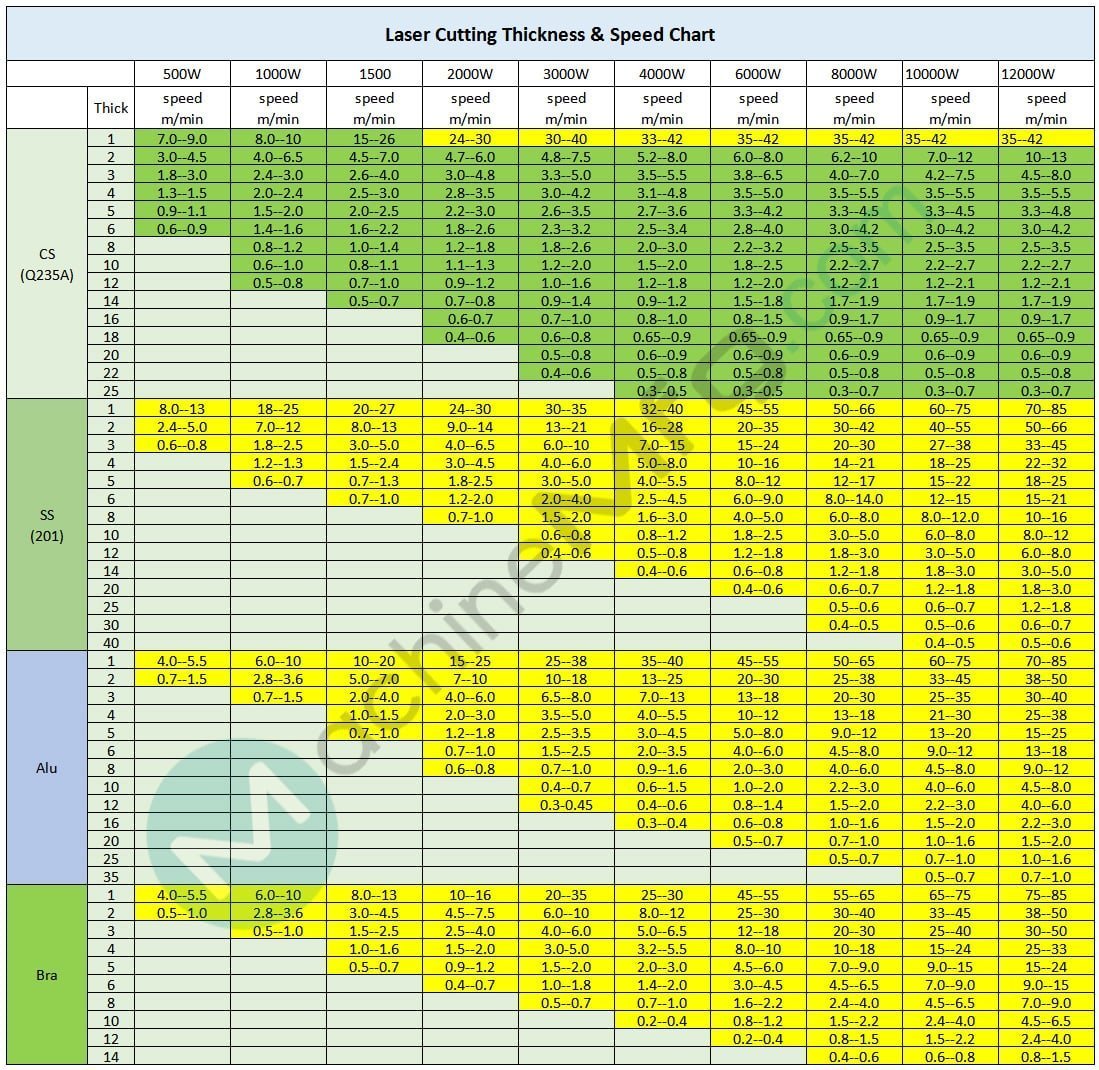

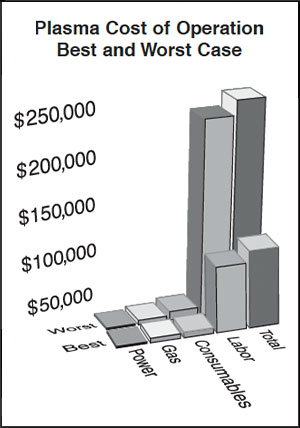

In the heaviest thickness the punch plasma maintains a 40 percent cost advantage over laser cutting. The length of all the cuts in the design can be used as a rough estimate of the cutting time consumed. You can configure various device parameters including device type video standard and channel number and the channel parameters. Chart 4 illustrates the characteristics for the four cutting lasers.

It is not recommended to continuously process for a long time. Entry level laser machine costing from 2000 10000 air blower exhaust fan. For the cutting of high anti corrosive materials such as copper and aluminum attention should be paid to adjusting the process. To price laser cutting online we need to extract two pieces of info from uploaded design files.

Material type and thickness cut distance and number of holes. Approximately 80 of the time while the program is running the laser is cutting this is the majority of the processing time. Hi everyone this is amy from thunderlaser. In this scenario the precision plasma cutting process has the highest cost of the three processes.

Any free or paid vector designing softwares 0 5000. The area of a box surrounding the design called the bounding box is the amount of material needed.