Laser Hole Drilling Process

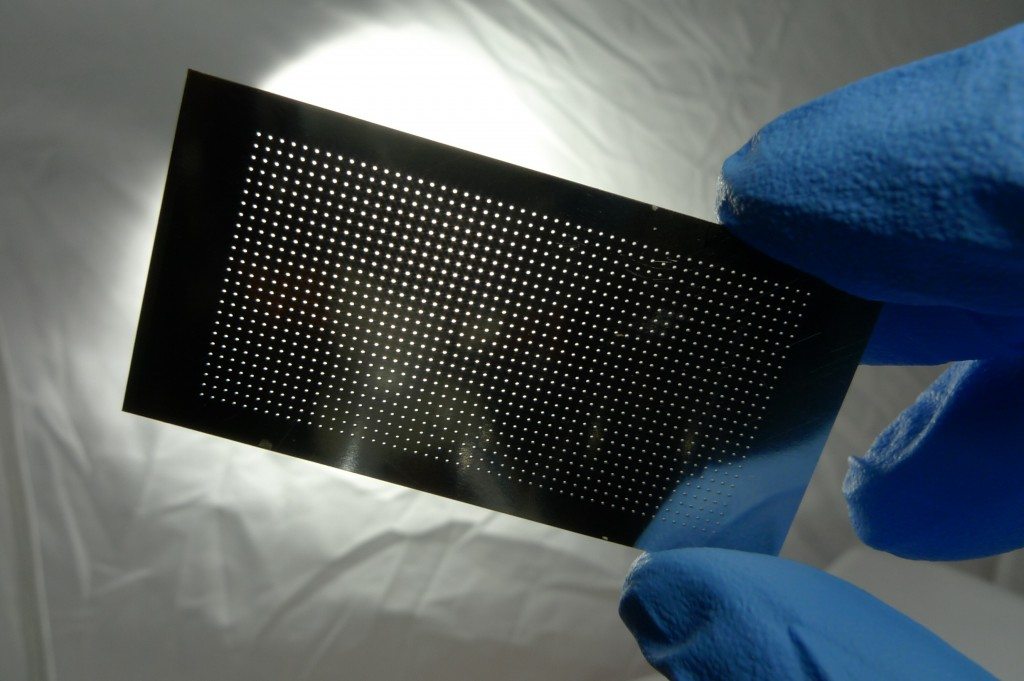

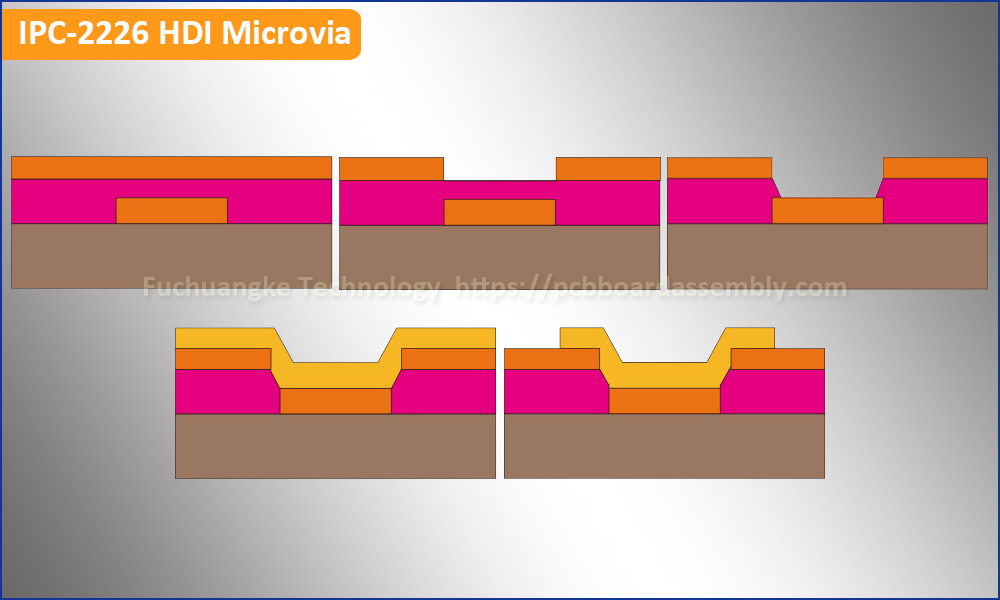

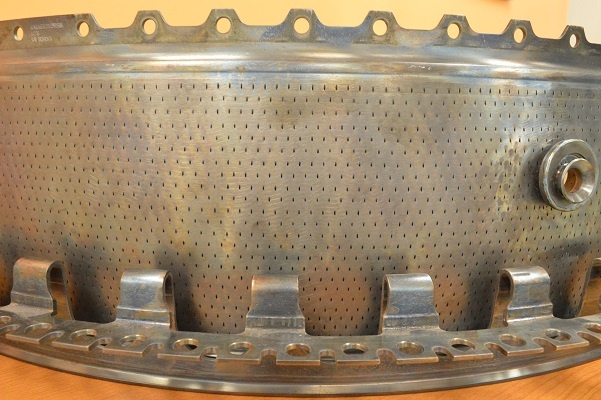

Lasers can be focussed to very small spots the very small holes in ink jet nozzles or the micro vias in smart phone printed circuit boards are created with our excimer or co2 lasers.

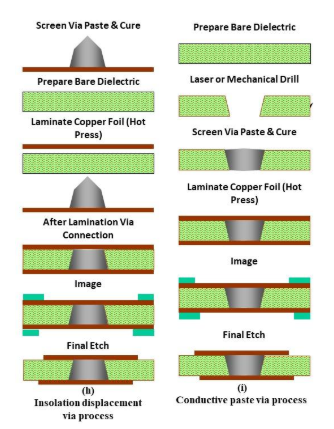

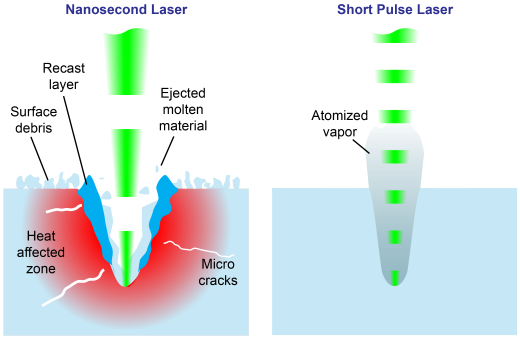

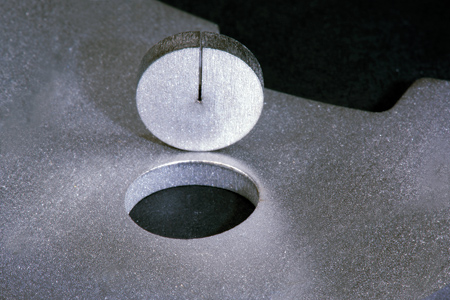

Laser hole drilling process. Laser drilling is the process of creating thru holes referred to as popped holes or percussion drilled holes by repeatedly pulsing focused laser energy on a material. Laser drilling is a non contact process that uses focused high energy density light to ablate material and drill holes in a wide variety of materials. The difference however between percussion laser drilling and single shot laser drilling is that the size of the beam being used within percussion laser drilling is changed throughout the process changing the size of the hole throughout the process. This is essential in order to define a suitable drilling strategy modify process parameters accordingly during the drilling process and to use process gases effectively.

Laser drilling is a non contact process where the workpiece and the tool do not come in contact with each other. Laser drilling utilizing the trepanning method can also produce proportionately larger exit holes by tilting the laser beam within an already drilled. Laser drilling is a non contact process meaning that unlike conventional drills the laser doesn t physically touch the material it is working with itself meaning that the only mark that is left is the hole that has been drilled. If larger holes are required the laser is moved around the circumference of the popped hole until the desired diameter is created.

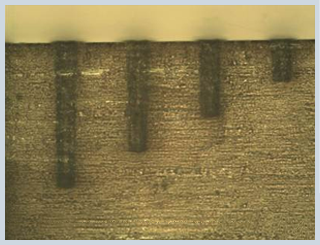

Gfh gmbh has been involved in the production of laser drilled micro holes since it was founded. Percussion laser drilling therefore typically creates deeper and more precise holes with. Laser drilling is the process of repeatedly pulsing focused laser energy at a material vaporizing layer after layer until the desired depth is achieved. Laser drilling of micro holes is a key area for precision laser micromachining.

Laser drilling in a trepanned spiral pattern begins in the approximate center of the laser drilled hole and prevents hole inconsistencies related to the start stop of the laser beam. The smallest hole diameter that can be drilled by this operation is about 6 mils 0 006. The laser drills are more precise can drill way smaller holes. The anv laser team has extensive experience in laser drilling with the know how to precisely control all the parameters that are critical to achieving precise and predictable hole drilling.

This drilling technology implements drill bits. The drilling of small holes is one of the most common applications of the excimer and co2 lasers. Laser micro hole drilling is widely applied to the creation of precisely controlled orifices for applications that demand a combination of small diameter exceptional quality and exacting tolerances.