Laser Paint Removal Uk

P laser develops and produces the world s most advanced industrial laser equipment for manual and automated use.

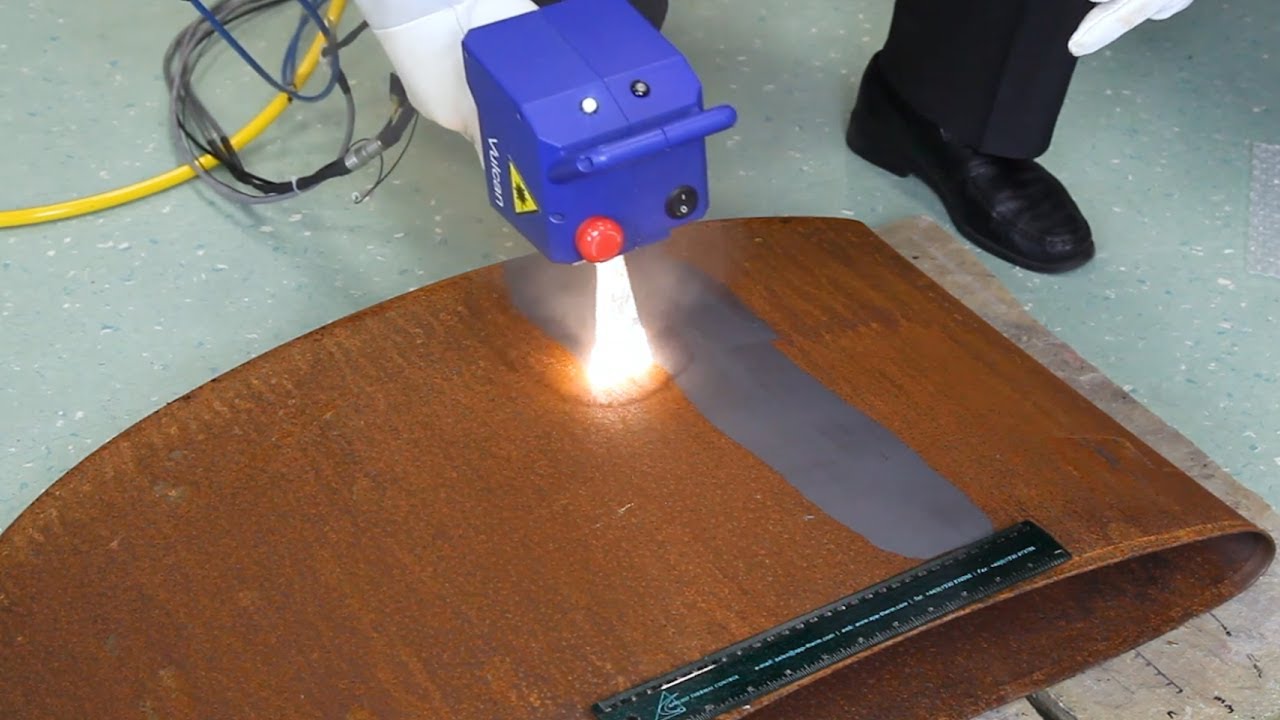

Laser paint removal uk. The laser beam is pulsed onto the part with a precise energy density. The handheld laser cleaners process a wide range of materials with special attention to highly reflective metals. The most popular and proven applications of the cleantech handheld laser cleaning systems are parts cleaning paint removal rust removal and surface conditioning. If you are looking for a cleaning process that requires no abrasive consumables no toxic chemicals no mess to clean up afterwards no damage to metal or ceramic parts then we can provide such a system.

A list of all other applicable processes for the cleantech. Our industrial laser cleaning systems range from 20 to 1000 watt of extremely accurate cleaning power. Laser paint removal laser paint removal is a process through which a paint layer is removed from a surface without damaging the substrate. It s also known as laser coating removal and de coating.

What makes this laser device even more intriguing is the fact that it has an on board hoover system that immediately sucks up the vaporised rust making the entire rust removal process as clean. Laser cleaning systems combine power and versatility. Us dod maintenance excellence award the office of the secretary of defense awarded lasertronics the 2009 maintenance excellence medal for contributions to the automatic rotor blade stripping system at. Federal aviation administration has endorsed the use of lasertronics as the only laser coating removal system for all aluminum aircraft.

Laser cleaning machines and laser rust removal. Innovative laser ablation technology for industrial surface treatment cleaning and paint removal applications. That miraculous creation shown is the work of belgian company p laser and can be used as a handheld tool to carry out such tasks as rust heavy paint and grease removal along with a variety of. It is higher than the paint ablation threshold but lower than the substrate ablation threshold.

Laser technology removes contaminants production residue and coatings without damaging the substrate.